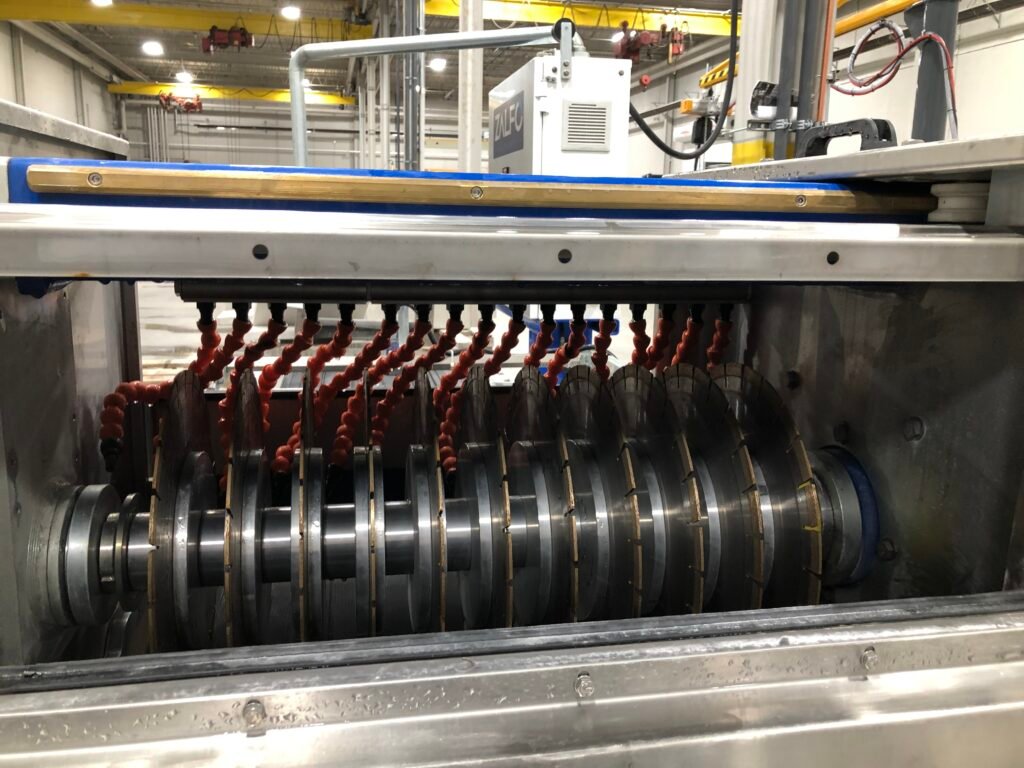

Stone is continuously cut along the conveying direction, while the blades are in slight contact with the conveying belt. Z axis (blade tip to conveying surface) adjustment is performed via pushbutton controls. We manufacture various models with the following range.

- 13″ to 26″ wide conveying surface

- One to three spindles for step cutting, milling + cutting or profiling + cutting

- 3/8″ to 8″ thickness cutting with 12″ to 20″ blades

- Up to 30 blades per spindle with quick swapping blade holder shafts

- Short or long frames for 12″ to 60″ inch incoming product length

- 36 hp to 46 hp direct drive spindle motors with no belt drives

- Blade up – down (all models), in – out (two and three spindles) for step cutting adjustment (0.003″ increments)

- VFD controlled conveying speeds up to 11 ft/min

- Tile flap mechanism for net shape tile production